Industrial Water Treatment Plant Etten

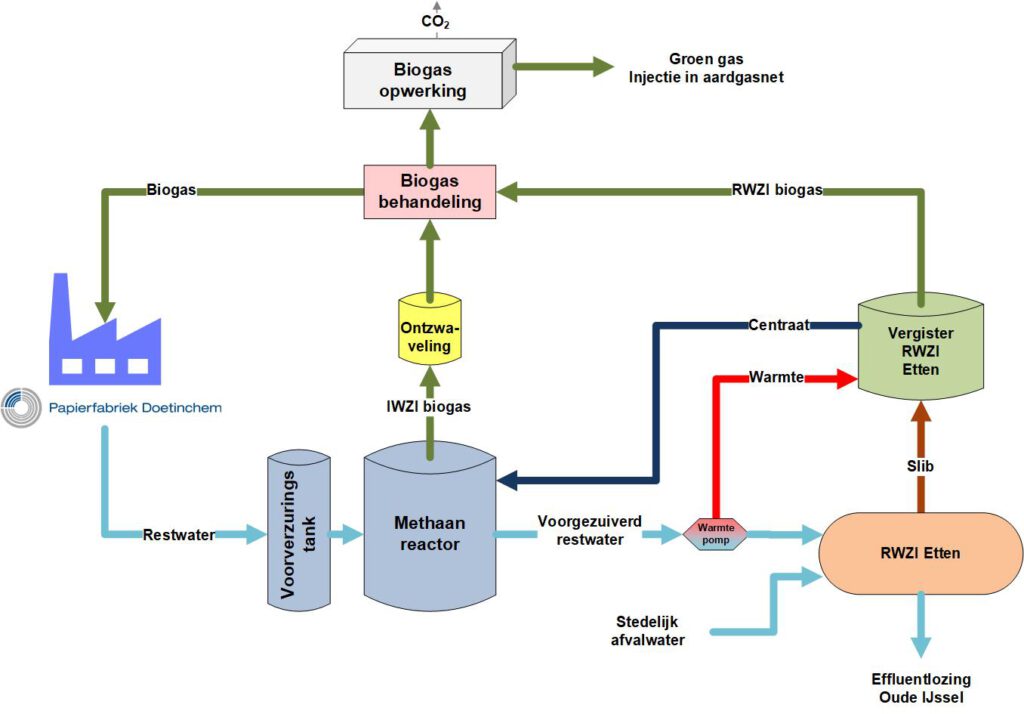

Waterstromen treats the residual water from the Doetinchem Papermill at the Etten location. By pumping the residual water via a pressure pipe from the papermill separately to location Etten, the residual water can be treated anaerobically, and biogas is produced. The biogas is supplied, together with biogas produced in the sewage sludge fermentation of STP Etten, to Papierfabriek Doetinchem via a biogas pipeline. In addition, a part of the biogas is upgraded to grid gas by means of biogas upgrading and injected into the natural gas network.

The residual water from Papierfabriek Doetinchem contains a lot of organic matter and is relatively warm at about 35°C. This residual water is ideal for anaerobic treatment with the production of biogas. However, the location of the papermill in the center of Doetinchem is not really suitable for an anaerobic reactor at its site.

The residual water is therefore pumped with a pressure pipe to the location at STP Etten. By pumping the residual water with a separate pressure pipe and not mixing it with sewage (which is relatively thin and cold), it remains possible to treat the residual water anaerobically. The 4.5 km pressure pipeline was constructed especially for this project.

In the new anaerobic treatment installation at the location Etten, bacteria convert the organic matter into biogas. These bacteria need nutrients. Instead of purchasing nutrients, centrate is used as a nutrient source. Centrate is a residual flow from the STP after fermentation and dewatering the sewage sludge. Due to its use as a nutrient source, less electricity is required for processing of this residual flow in the STP.

The effluent after the anaerobic treatment is still relatively warm. This heat is recovered with a heat pump and used for the sludge digestion of the STP. The sewage sludge orginates from urban waste water. Biogas is also produced during this sludge digestion.

The biogas from the residual water from the papermill and from the sludge digestion is directed to Papierfabriek Doetinchem via a biogas pipeline. This biogas pipeline was laid in the same route as the pressure pipeline for the residual water. At the Papierfabriek Doetinchem, the biogas is used for steam production, which is required for the production of paper.

In addition, part of the biogas is upgraded to grid gas and injected into the natural gas network. By both supplying biogas to the papermill and upgrading to grid gas, maximum utilization of the biogas is achieved.

In total, 2 million m3 of biogas is produced during the anaerobic treatment and sludge digestion, which corresponds to 1.5 million m3 of natural gas equivalent. Because a large part of the waste load is processed in the anaerobic treatment installation, electricity and sludge production are also saved in the STP.